MICROSCOPIC OBSERVATION OF THE PROCESS OF FORMATION AND RUPTURE OF EMULSIONS OF EXTRA-HEAVY CRUDE OILS FROM THE ORINOCO OIL BELT

Abstract

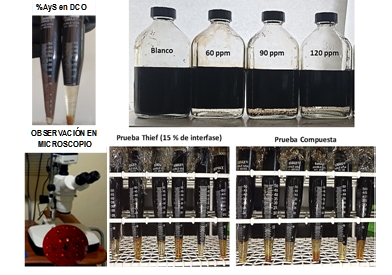

In order to provide adequate chemical solutions to the operational reality of the oilfields, it was proposed to document and interpret the process of formation and breaking of emulsions using the microscopic observation technique (Motic SMZ-168 microscope, transmitted light, 0.65X lens and 5X zoom). The research was carried out with samples of diluted extra-heavy crude oil from a fluid processing center located in the Orinoco Oil Belt, measuring its physicochemical properties and testing the performance of demulsifiers. For the formulation of these products, the bases of surface chemistry, optimal formulation correlations and material balances were used; selecting the components according to their physicochemical characteristics and specific functions in the formula. For the cases analyzed, it was a W/O (water-in-oil) emulsion with a polydisperse droplet size distribution. In the samples without demulsifier (white), a significant number of droplets were observed, of larger size and irregular shape compared to the samples of dehydrated crude oil (residual water droplets in smaller quantity and size, spherical geometry). The observed changes are due to the combined effect of the different variables involved in the dehydration process: physical (line travel, agitation, contact time, sedimentation velocity, electric field), thermodynamic (temperature, pressure, chemical potential, voltage gradient) and kinetic (adsorption of surfactant molecules). Process efficiency in bottle tests was determined as a function of water separated in the first thirty minutes (field residence time) up to 120 min (laboratory time); with significant values at the 120 ppm concentration of demulsifier. The fast breaker showed good performance at 40 ppm. The titration tests allowed us to know the effectiveness of the chemical treatment, make adjustments in the formula and in the operational requirements for a rapid resolution of the emulsion.Downloads

Downloads

Published

How to Cite

Issue

Section

License

The authors of papers accepted for publication by the RLMM, should recognize the complete transfer of copyright (in all languages) to the RLMM. This transfer includes the right by the RLMM to adapt the article for digital or printed reproduction without altering the written content and information displayed in tables or figures within. The authors retain the copyright and guarantee the journal the right to be the first publication of the work as well as licensed under a Creative Commons Attribution License 4.0 Internacional (CC BY 4.0) which allows others to share the work with an acknowledgment of the authorship of the work and the initial publication in this journal.